By JOHN T. WARD

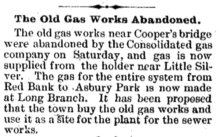

More than a century after it served as a gas works, a riverfront Red Bank property may get some 20th-century environmental remediation.

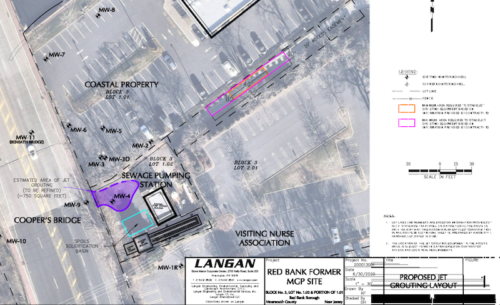

Coal tar and other toxic wastes beneath the town’s Bodman Place sewage pumping station overlooking the Navesink are slated to be immobilized by technology known as ‘jet grouting,’ according to borough officials.

Tied into the then-new sanitary sewer system, the site was used as a “sewage disposal facility” until 1940, when it was redeveloped as a sewage treatment plant. It has served as a sewage pump station since 1961; the sewage treatment plant was shut down and decommissioned in the early 1980s, Shehady said.

Despite Red Bank’s 124-year ownership of the property, a JCP&L entity “buried the waste underground” and is deemed responsible by the New Jersey Department of Environmental Protection for remediation, borough Attorney Greg Cannon told the council at its semimonthly meeting Wednesday night.

The agency “has lists of all these old industrial sites and where they are, and the people responsible for cleaning them up,” he said.

At the Bodman Place site, on a peninsula known as Oyster Point, coal tar and other “constituents” of gas manufacturing have been identified in soil and groundwater “at concentrations exceeding” the DEP’s remediation standards, according to an August, 2018 letter to Shehady from a Darren T. Hopper, senior project manager at Langan Engineering & Environmental Services, under contract to JCP&L.

The area of contamination extends beneath the sidewalk and northbound approach to the bridge, and as far down as 24 feet.

Still, the material “must be remediated to the extent practicable to satisfy NJDEP requirements,” Hopper wrote.

In another letter, dated March 11, Hopper told Shehady that Langan hopes to stabilize the material through “jet grouting.” He described the work as a drilling technique that uses “high-pressure, high velocity jets to hydraulically erode, mix and partially replace the soil with a cement-grout slurry to create a low permeability and high strength mass.”

The project involves “significant risks because of the presence of utilities (including sewer piping) and the pumping station infrastructure,” the letter says.

Before it can proceed with the remediation, soil boring work must be completed to precisely identify all underground utilities, Hopper wrote. Langan also needs to obtain permission from owners of neighboring properties to stage equipment.

By informal consensus, the council agreed to allow the firm to conduct the next stage of the work, for which the borough would be indemnified, Shehady said. Langan must later come back to the borough with a detailed plan for the remediation work itself, he said.

Shehady told redbankgreen the borough is cooperating because “we want to ensure that JCP&L maximizes its remediation efforts.” The work will be done at no cost to the town, he said.

If you value the news coverage provided by redbankgreen, please become a paying member. Click here for details about our new, free newsletter and membership information.